OCTG Pipe inspection Services

• Magnetic paricle Inspection

• Liquid penetrant Inspection

• Ultrasonic testing

• Drill Pipe Inspection API & DS-1

• BHA inspection API & DS-1

Rig inspection, OCTG Pipe inspection Services and tubular inspection from PETROCON-identifies defects before they cause serious damage, assures smooth operation and reduces financial risks.

Your rigs, pipes and oilfield tubulars are vulnerable to corrosion, cracking, third-party damage and manufacturing flaws. Our rig inspection, OCTG Pipe inspection Services and tubular inspection services detect defects and discontinuities before they cause serious damage, assuring smooth operation and reducing financial risks.

WHY USE RIG INSPECTION, OCTG Pipe inspection Services AND TUBULAR INSPECTION FROM PETROCON?

With a commitment to maintaining the standards of the oil and gas industry, we offer you cost-effective and professional services to ensure the safety and reliability of your operations. We can help you:

• Monitor the condition of your rigs, drill pipes and tubular equipment

• Detect and locate internal and external, corrosion, pitting, cuts, gouges, wall loss, and fatigue cracks before they result in severe damage

• Ensure the operational integrity of your rigs, pipes and oilfield tubulars and comply with the latest regulations and standards

• Manage safety cost-effectively through comprehensive inspection and risk ranking

• Deploy the most appropriate action for damage that cannot be detected in advance

• Predict and avoid potential failures

TRUSTED RIG INSPECTION, OCTG Pipe inspection Services AND TUBULAR INSPECTION FROM A WORLD LEADER

As a world-leading provider of comprehensive rig, pipe and oil tubular safety, inspection and maintenance services, you can rest assured that your project is in safe hands.

With more than 1,000 projects completed for the oil and gas industry, we offer you unrivaled experience, expertise, specialized engineers and technicians, and worldwide resources. That is why we are the first choice for major operators and drilling contractors across the globe.

OUR SERVICES :

1. Rig inspection

2. OCTG Pipe inspection Services/tubular inspection

3. Non-destructive testing (NDT) techniques

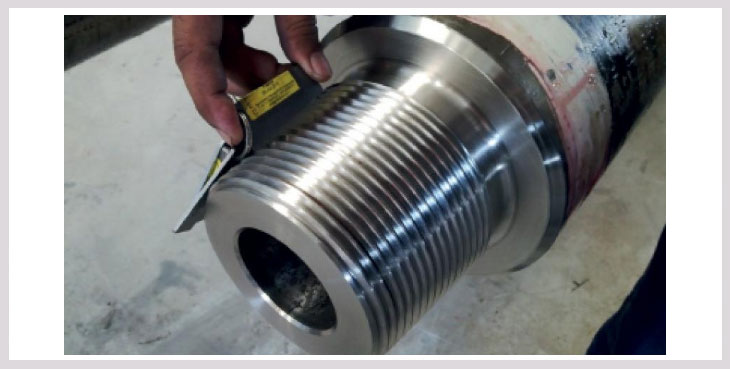

Drill pipe and tubular inspection:

Drill pipe & tubular inspection services are offered by PETROCON Services in accordance with API, DS-1 & NS-2 standards. With the most advanced inspection tools and methods in the industry, PETROCON Services undertakes quality inspections and management services in which large quantities of tubulars, bottom hole assemblies and other drilling equipment are inspected and controlled.

Through our services, we give accurate and comprehensive reports of inspection on time to minimise and ultimately eliminate downtime on the assets of our customers.

1. Disciplines : Piping , Mechanical , Civil & Structures , Electrical & Instrumentation

2. lnnovative Piping Design Services

3. Expert in Static/Rotaty Equipment Design

4. Civil & Structures, Concrete design under one roof

5. Plant Electrical Engineering Design

6. Plant instrumentation Design using Automation

Our inspection management services encompass:

Drill pipe & HWDP-Category 1-5

Drill Collars, Stabilisers, Subs, Pup Joints

Casing & Tubing inspection

Hardness Testing

Full Length API Drift Testing

Thread Seal Testing.

Bottom Hole assembly inspection services.:

PETROCON provide BHA inspection covering the following types of inspection for all BHA types of drilling tubular:

1. Dimensional Inspection

2. Visual Inspection

3. Magnetic Particle Inspection

4. Dye Penetrant Inspection

5. Ultrasonic Wall Thickness Inspection

6. Refacing

BHA inspections will conform to API RP7, DS1, NS2, or any other standards nominated by our customers. In conjunction with drill pipe and BHA inspection STAG TIC Ltd can field reface rotary shouldered connections if required, alleviating the need to repair minor seal face damage via machine shop, saving valuable time and money. We have the capability to reface a range of API connections, including NC38, NC46, NC50, 6 5/8” REG, 7 5/8” REG, 5 ½” FH and 6 5/8” FH.

BOTTOM HOLE ASSEMBLY (BHA) INSPECTION

We can provide BHA inspections on any drilling component used in the industry to check conformation to API RP7G T.H.Hill DS1, NS2 , or any other standards requested by the client.

BHA Inspection includes

• Drill Collars

• Heavy Weight Drill Pipe

• Cross Over Subs

• Stabilizers

• Reamers

• Bit Subs

• Down Hole BHA

• Special tools : MWD, Mud motors/turbines

• Fishing tools, etc

• BHA Types of Inspection

• Visual Threads Inspection

• lacklight Inspection of connection

•Threads Profiling Gauge

• Dimensional Inspection

• Visual Tube Inspection

• Magnetic Particle Inspection

• Dye Penetrant Inspection

• Refacing

Milling and Fishing Services

When well intervention services are needed, reliability and efficiency are key aspects in keeping our customers operational focus in mind. These efficiencies are gained when you have skilled well intervention personnel who can oversee the entire operation, with the right tools to address the intervention challenge.Halliburton has that expertise, gained from decades of knowledge and experience.

We offer a broad inventory tools that are specifically designed for thru tubing applications

Whether you need a tool to remove composite bridge plugs, cast iron bridge plugs, cement, sand, scale or fish obstructions from a wellbore, we address each particular well condition and offer a solution to optimize all aspects of fishing, retrieving or milling operations.

We also maintain a full line of fishing tools made specifically for coiled tubing operations.

• Bi-Directional CT Jars

• Venturi Junk Baskets

• Hydrualic and Mechanical Overshots

• Continuous Overshots and Fishing CT

• Vibration Technology for Horizontal Applications

Retrieving loose objects, wireline, tubing or junk left in the wellbore can be time consuming. With the right tool and skilled personnel, we can minimize downtime and help our customers quickly resume normal operations.

And most important, our expert tool operators and supervisors are trained to understand how our tools are built, maintained and repaired and they know how they should operate in real-world conditions.

Loose lifting gears survey, inspection and management